Understanding The Total Cost of Your Logistics & Supply Chain

The # 1 Reason Companies Fail to Control Their Costs

Two years ago, we met with a global manufacturer who was undertaking a major cost cutting initiative for the North American operations. A central point of the initiative encompassed reducing the costs for supporting logistics.

This led them to embark on a freight consolidation initiative. When we met with them, they told us that the objective was to reduce their freight costs by 10%, which in their case was approximately $3 million.

In response, we asked them a question that we have learned from our 25 years of experience is the most important question any company can ask when looking to reduce or control their costs.

Is your goal to eliminate $3 million of costs from your logistics operation, or is it to reduce your “spend” by $3 million?

Their initial response did not surprise us. They said, “Well, of course it’s to eliminate costs, but what’s the difference?”

Understanding the answer to this question is critical if costs are an issue for your company. The single biggest consequence from the deep recession we have gone through (and some would say are still in the midst of) is the paramount need to do more and to do better with fewer resources.

If you’re like many of our customers, your customers are putting more and more pressure on you everyday on both your pricing and what they expect from you. They want, no, they need to pay less and get more.

What is a distributor to do?

Typically they put pressure on their vendors to reduce their prices.

Now, if this process actually worked, companies wouldn’t have cost control problems like they do.The fundamental mistake made by companies trying to control or reduce costs is that they look at costs as a zero sum game. They act as if they can reduce what they are spending on a line item like “freight” or “trucking” and expect that the “savings” will go right to the bottom line.

Unfortunately it doesn’t. Logistics is a complex, dynamic system; and any time you change one piece of it – every other piece is impacted, positively or negatively. When your focus is on spending alone, you are typically going to overlook many areas that can both positively and negatively impact the cost and opportunity sides of the equation.

It’s far more valuable to look at every function in your business through the prism of the total cost of ownership. Understanding the total cost of ownership means calculating the direct and indirect costs of a process, including the hard and soft costs. In logistics the indirect and soft costs can dwarf the direct costs.

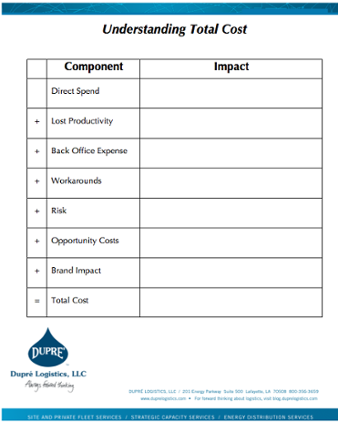

When reviewing total cost of logistics, we encourage companies to utilize this worksheet:

Direct spend is the easiest input to measure, and as a result it carries a disproportionate focus when reviewing options. The problem, especially in the trucking and logistics arena, is that the fastest way for a vendor to lower direct spend (and gain an apparent advantage in the market) is to cause the costs in every other area to increase.

We are not saying that the direct cost isn’t an important measurement – it is. In our experience, many companies are spending too much.

However, it is far more effective to take a partnership approach to such a critical function. Partners will help you understand your total costs. They’ll work with you to manage the trade-offs inherent in the process. Better still, they’ll do it constantly, not just at contract renewal time.

When you look at your logistics and trucking partners through the prism of total cost, you’ll be able to permanently move the cost needle in your favor, and ensure that you control costs – in good times and bad.